Waterjet cutting is used by wide range of industries. Leading car manufacturers, technology firms, heavy industries all utilize waterjet cutting for their various needs. This is possible due to waterjet's simple and effective nature. Waterjets are able to cut a material by applying ultra high pressured water on a single point. If water alone is not enough to break down the target material, abrasive materials such as garnet can be inserted into the mix to break through the toughest of materials.

This ability of customization is something that allows waterjets to be highly applicable to virtually any industry. Below are just some of the materials that can be processed by waterjets.

-

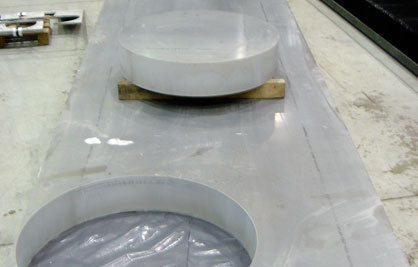

Metals: aluminium, steel, iron, magnesium

-

Wood: natural wood, particle boards

-

Stones: granite, marble

-

Others: plastic, rubber

Wide variety of materials mentioned above can be used by a single company to create a complex object, such as electronics. It can also mean that waterjet can also satisfy a single need in multiple range of companies. Waterjets are simply the easiest solution which can work for almost any company. Being able to obtain waterjet cutting service or access to the equipment can be a significant advantage over others for a company since it increases efficiency and the potential of the company.

Waterjet facilities are basically a one stop shop. A single place where many of your needs may be met. Waterjets can offer faster processing upon demand and can also provide the best possible quality upon demand. Flexibility of waterjet's capability allows companies to easily leverage the technology. From small parts for a machinery to entire frame of an automobile, waterjet's usefulness is only limited by the imagination of its user.

The following are just some of the large industries out there which utilizes waterjet solutions:

-

Automotive industry

-

Heavy machinery

-

Electronics

-

Construction

-

Manufacturing

-

Furnishing

-

Food processing

-

Craftsmen

Due to such wide penetration in various industries, waterjet facilities are quickly becoming experts in their primary client's fields. If the waterjet facility specializes in metal fabrication due to majority of their clients requesting that service, they will eventually become more specialized towards those materials. Having access to service providers who have great understanding of your industry is likely to lead to better results.

Waterjet's highly flexible nature allows it to be one of the preferred methods in the business. Its value is increasing daily as newer technology are being developed to further increase its efficiency and capability. It is one technology which a company can rely on even if they change their primary business model. Reliable solutions are what allows countless number of businesses to operate with efficiency in the field.